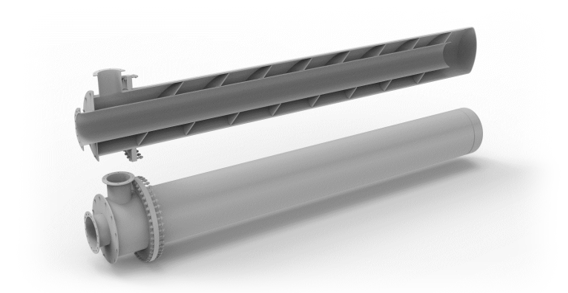

Our Concentric Firetube Design eliminates the direct flame impingement on the fluid boundary, ensuring more uniform heat distribution compared to the U-tube style firetube. The absence of localized “hot spots” prevents coking on the shell, enhancing the operational safety of the unit. The firetube is built using standard pipes, weld caps, and single-penetration concentric holes in ASME flange covers. It can be constricted to and stamped as a Section VIII Div I Vessel, ensuring compliance with existing design codes. In addition, there is a Patent Pending USSN 29/970,805 for our design.

Enhanced safety is provided by removing the inner tube which allows for inspections without removing the pressure-bearing shell, enabling vessel operation during maintenance. A strict adherence to design codes makes these firetubes significantly safer than miter-joint U-Tube designs. Moreover, our firetubes are serialized for traceability.

Customers can expect an extended lifespan because the pressure-bearing shell can last dramatically longer, potentially matching the lifespan of the heater treater itself. The inner tube serves as the primary consumable part, simplifying maintenance and replacement. Performance advantages include efficient gas flow, which eliminates the inefficient U-Tube common path for hot gas through the center of the pipe and up the flue. A larger surface area than U-Tube designs allows for improved heat exchange efficiency and a larger chamber in the flighting section slows gas velocity, contributing to more efficient heat transfer.